Rapid and Innovative R&D

Conventional Challenges

Delayed timelines, high costs, limited flexibility, insufficient iteration cycles

Divergent Solution

End-to-end design and production solution cuts development time & cost by over 50% while maintaining flexibility for new design iterations.

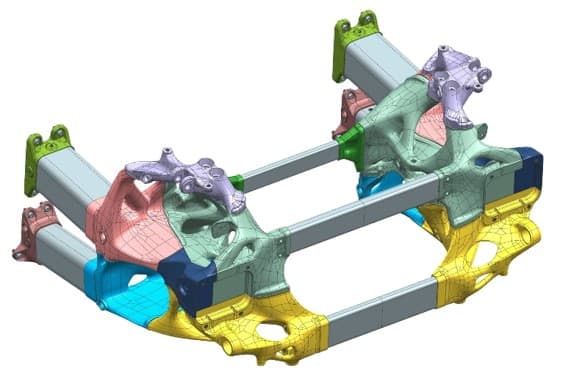

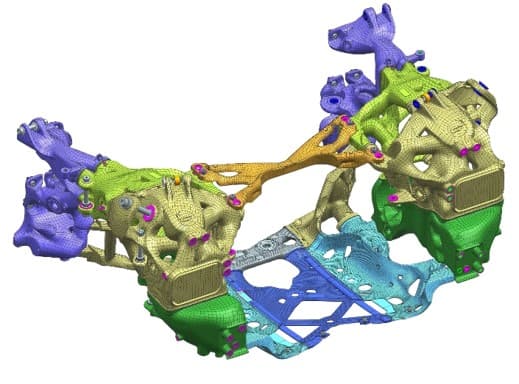

By leveraging the Divergent Adaptive Production System, the Czinger 21C engineering team went through a complete front and rear frame and suspension redesign within a 3-month cycle – from off-track to on-track – widening the vehicle from 1850 mm to 2050 mm. The redesigned 21C chassis ultimately delivered lap-record-breaking performances at Laguna Seca and Circuit of the Americas.